The Superior Works: Patrick's Blood and Gore Planes #141 - #196

Quick Find: #141, #143, #144, #146, #147, #148, #164, #171, #180, #181, #182, #190, #190W, #191, #192, #193, #193A, #193B, #194, #195, #196

#141 Bullnose plow, filletster and matching plane, 9 1/4"L, various widths, 5 1/2lbs, 1887-1918. *

This, and the following

plane, are the bull nose versions of the #41 and #43. Two interchangeable nose

pieces are provided with

these two planes; one that functions as a bull nose, and

one that's for normal

ploughing. One of the arms (on which the fence fastens)

threads into the main

casting near the handle, but the other slips through the

casting and instead

threads into the installed nose piece. This sorta is a

pain in the butt when

you have to change nose pieces, but such is the life of a

manual laborer.

This, and the following

plane, are the bull nose versions of the #41 and #43. Two interchangeable nose

pieces are provided with

these two planes; one that functions as a bull nose, and

one that's for normal

ploughing. One of the arms (on which the fence fastens)

threads into the main

casting near the handle, but the other slips through the

casting and instead

threads into the installed nose piece. This sorta is a

pain in the butt when

you have to change nose pieces, but such is the life of a

manual laborer.

With the bull nose attachment fixed to the plane, the

plane can work into a

1/2" hole; i.e., when making a stopped groove, you can

terminate the

groove with a 1/2" diameter hole, and the plane can work up

to it. When

working bull nose with the plane, the bullnose piece often

slams into the end

of the work and can become munged up. Check this area out.

The early models are japanned with the deep floral

casting that's common on

the Miller's Patents which inspired them. They later became

fully nickel

plated, including the adjusting screws and chip deflector,

and they don't have

the depth to the floral motifs that the earlier models do.

Starting ca. 1905,

the floral casting was eliminated, and the plane became just

another ugly chunk

of 20th century metalwork.

While the cutters have a similar appearance to those

provided on the

conventional Miller's Patents, the cutters shipped with

these planes are not

the same thickness; the tool's cutters are thinner in cross

section. The plane

is normally found with its fillister bed missing, and should

you own the nickel

plated version of the plane and are missing the fillister

bed, you have my best

wishes and positive vibes for finding a nickel plated bed.

The bull nose

attachment is also commonly MIA.

A single fence was provided with the plane. This

fence, like those used on

the later #41's and other planes like the #45, has two pair of holes in it

so that one fence can

serve both grooving and fillistering functions; the top

set of holes are used

for fillistering work, while the bottom set of holes are

normally used for

ploughing. Check the fence casting all over for any signs

of cracking or

damage.

The demands in the workshop are rather limited for a

plane such as this

(quick, how many times you ever make stopped grooves?) so

sales of the plane

were weak when compared to the main line of Miller's

Patents. Oh yeah, you

can't use the fillister bed with the bull nose piece in

place. Sad news, I

realize, but deal with it.

#143 Bullnose plow and matching plane, 9 1/4"L, various widths, 4 3/8lbs, 1887-1943. *

This plane follows the same evolution as the #141, except for one notable exception - the fence was provided with a rosewood face, like on the #45 and #55, starting in the mid-1930's.

A scarce version of this plane, made during the last

few years of its life,

has the number "143" cast into it. All the other planes of

this style

- the #41,

#42,

#43,

#44,

and #141 -

never had any numbers cast into them.

#144 Corner rounding plane, 7 1/2"L, various widths, 1 1/8lbs, 1925-1943. *

These are the Radi

planes (or whatever their names are of those new junk tools

sold at major tool

joints) of yesterday, and are the first hint of bad things

to come where the

depths to which Stanley would plunge themselves to develop

new ideas was a

bottomless abyss. Things are pretty much downhill from here

in the New Chunks

of Iron Department what were spawned during Stanley's

boring-20's onward.

These are the Radi

planes (or whatever their names are of those new junk tools

sold at major tool

joints) of yesterday, and are the first hint of bad things

to come where the

depths to which Stanley would plunge themselves to develop

new ideas was a

bottomless abyss. Things are pretty much downhill from here

in the New Chunks

of Iron Department what were spawned during Stanley's

boring-20's onward.

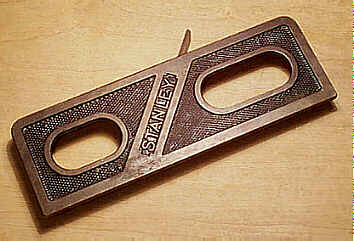

They are rather strange looking planes - a

rectangular chunk of cast iron,

with an eliptical cutout forward of the cutter and another

behind the cutter. A

diagonal groove is machined, from top to bottom at the

midpoint of the plane,

to receive the cutter. A raised portion of the casting,

forward of the groove,

carries a slotted and flat-headed screw, which is used to

secure the cutter in

position (you need a screwdriver - a real one and maybe the

cocktail to loosen

you up - to operate this plane). The sole is shaped to

approximately

one-quarter of an arc. The casting is japanned. "STANLEY" is

embossed

on the side opposite the cutter; the background to either

side of the embossing

is cross-hatched in a manner that's similar to a better

machinist's combination

square.

The plane comes in

three

different sizes - 1/4", 3/8", and 1/2" (sized by the radius

of a

circle). The 3/8" model is the most common, with the 1/4"

the least

encountered. The cutter sticks up above the casting, and the

vast majority of

the cutters have the sweetheart logo stamped into them.

Proper cutters also

have the plane's working diameter stamped into them, right

about where the

cutter securing screw holds it in place, e.g., "1/2 CIR."

Oddly

enough, this same stamp, but in smaller letters, is found on

the 'fence' right

behind cutter. Check that the cutter has the proper stamps

on it to ensure that

it isn't a replacement. The plane's have "No. 144" embossed

in the

casting, along with the patent date of "U.S.PAT. 10-6-25",

but the

earliest ones just have "PAT APPL FOR" embossed in them.

The plane comes in

three

different sizes - 1/4", 3/8", and 1/2" (sized by the radius

of a

circle). The 3/8" model is the most common, with the 1/4"

the least

encountered. The cutter sticks up above the casting, and the

vast majority of

the cutters have the sweetheart logo stamped into them.

Proper cutters also

have the plane's working diameter stamped into them, right

about where the

cutter securing screw holds it in place, e.g., "1/2 CIR."

Oddly

enough, this same stamp, but in smaller letters, is found on

the 'fence' right

behind cutter. Check that the cutter has the proper stamps

on it to ensure that

it isn't a replacement. The plane's have "No. 144" embossed

in the

casting, along with the patent date of "U.S.PAT. 10-6-25",

but the

earliest ones just have "PAT APPL FOR" embossed in them.

I find them very cumbersome to grip. Woe is you if

you decide to use one of

these things and your rear hand slips - that cutter is

hungry to slice not only

wood, but your hand as well. You can get the same results

that this plane

yields with an appropriately sized hollow, which is far, far

cheaper than one

of these planes.

The planes are very rugged since there's not much a

ham-fisted woodworker can

damage on them, and many of them are found in nearly unused

condition, which

should give the astute reader that the things don't work

worth a damn.

#146 Match plane (double end), 9"L, 1/8"W,

1

1/2lbs, 1905-1943.

This plane is the narrowest version of the more common #148. It cuts a groove 1/8" wide, and centers it on stock 3/8" thick. You can use it on stock up to 1/2" thick, since the tonguing cutter has its outer portion purposely made a bit wider than its inner portion.

#147 Match plane (double end), 9"L, 3/16"W, 1 7/8lbs, 1905-1943.

This plane is the narrower version of the more common #148. It cuts a groove 3/16" wide, and centers it on stock 5/8" stock. You can use it on stock up to 3/4" thick.

BTW, did you notice the effect the big war had on

this and the previous

three planes in this list? It was the perfect excuse for

Stanley to punt them

from their tool roster. Many of Stanley's planes, and tools

for that matter,

got bounced forever from production during WWII.

#148 Match plane (double end), 9"L, 1/4"W, 2 3/8lbs, 1905-1958.

This is the widest and

most common of three planes designed to match (tongue and

groove) boards, and,

for some strange reason, Stanley took to offering them

decades after the debut

of the successful #48 and #49 planes. That crazy and whacky

Stanley certainly

cherished either redundancy or total tool confusion by

making this series. This

plane centers a 1/4" groove on 7/8" stock, and can handle

stock up to

1" thick.

This is the widest and

most common of three planes designed to match (tongue and

groove) boards, and,

for some strange reason, Stanley took to offering them

decades after the debut

of the successful #48 and #49 planes. That crazy and whacky

Stanley certainly

cherished either redundancy or total tool confusion by

making this series. This

plane centers a 1/4" groove on 7/8" stock, and can handle

stock up to

1" thick.

All three are nickel plated metal, have their model

numbers cast into the

handle, and are sorta bizzare looking. They have two

opposing totes at opposite

ends of the plane, with the cutters positioned between them.

There are similar

wooden planes, made primarilly by the upstate NY makers,

which undoubtedly

inspired these later ones. They are used by pushing the

plane to make one of

the cuts, then flipping it, end for end, to make the other.

One plane does the

work that is commonly done by two. So, it's like having two,

two, two planes in

one.

There is a skate-like portion of the casting, which

acts as the fence, that

runs the length of the plane. To either side and above this

part of the casting

are the cutters - one for cutting the groove and one for

cutting the tongue.

Each cutter is secured by a captive, pivoting, and thumb

screw-activated lever

cap. I've seen several of the lever caps broken down below

the pivot point

and/or chipped at the leading edge of the lever cap, so keep

an open eye about

this area. The lever caps are attached to the main casting

with a screw, so

it's possible to make a proper repair by snarfing a part

from another example

that's otherwise terminal. Also, check the main casting as

it can sometimes be

found with a crack or chip down along the fence or one of

the 'soles'.

Many of the planes

have

replaced cutters, with the grooving cutter lifted from a #45. The

tonguing cutter is unique to the plane and it has a

slightly radiused heel.

Again, this cutter can sometimes be found as a replacement

from a #45. If you see

a notch cutout along the right side of the cutter, up

toward the heel, it's a

replacement.

Many of the planes

have

replaced cutters, with the grooving cutter lifted from a #45. The

tonguing cutter is unique to the plane and it has a

slightly radiused heel.

Again, this cutter can sometimes be found as a replacement

from a #45. If you see

a notch cutout along the right side of the cutter, up

toward the heel, it's a

replacement.

I think these planes are uncomfortable to use, not so

much on the right

hand, but on the left since it's the leading hand that has

to find some sort of

tolarable grip on a chunk of metal that bends back toward

your right hand. I

prefer the good ol' wooden ones, which don't suck the heat

out of your hands on

a cold day like these do. Plus, wooden planes don't rust or

suffer plane

leprosy (peeling nickel plating) like these do.

The first models of this plane, and its two smaller

brothers, has the patent

date, "PAT'D JAN 20-03", embossed in the handle. A japanned

version

of this plane was offered during WWII. It's not very common,

but good luck

finding the one collector who gives a rat's butt about it.

#164 Low angle plane, 9"L, 2"W, 3 1/4lbs,

1926-1943. *

This is one of Stanley's true rarities. Call me collect, if you ever find one.

Imagine taking the #62, and making it shorter, only

to find that there is

no room for the cutter adjustment mechanism. What do you

do? Why, you take the

conventional horizontally mounted Bailey adjustment, and

mount it vertically.

Problem solved? Nope. Bad managment decision here. The

plane was a horrible

flop, but those that did sell found more happy homes over

in England than they

did here in USofA, where we must be smarter it seems.

This plane has all the features the #62 does - an adjustable mouth, a

rosewood knob and

tote, and a cutter pitched at 12 degrees. It also suffers

the same problem that

the #62 does - the mouth can easily chip and the bottom

of the rosewood knob

can breakout due to frequent adjusting of the mouth. The

distinguishing

characteristic of this plane, other than the number "164"

cast into

it, is that the lever cap carries the brass depth

adjustment wheel and the

corresponding depth adjustment fork. The fork catches a

slot cut in a hybrid

cap iron secured to the cutter. This cap iron is not on

the cutter to break the

shaving (this is still a block plane with its cutter bevel

side up), but only

to adjust the cutter. It's very much like the cap iron

found on the #9, #11, #11 1/2, and #25, but it

differs from those in that it has graduations marked on

it.

#171 Door trim and router plane, 9"L (11" 1914 on), various widths, 3lbs, 1911-1934. *

Another stupid plane brought to you by a company known for many nightmares come to life. But wait, there are more soon to come, I promise. The New Britain Stinktank had no shame dumping all sorts of offal onto the tool-hungry masses of America.

This plane was designed to make the mortices that are

commonly found on

doors; things like butt hinges, face plates, strike plates,

escutcheons, etc.,

were its intent. Sorta like Norm's clever contraption for

his 'lectrical

routah, is what it does. It cuts mortices up to 3" wide and

5/16" deep.

There are two opposing rosewood totes to this plane,

which give it a

resemblance to the #148 style of planes. But, that's were the similarity

ends. This plane has

an adjustable fence, which can be removed to make the

plane work as a

conventional router. It has three different cutters, 3/8",

5/8", and

7/8" wide, which are screwed to an adjustable center post.

Directly above

the cutter is a coil spring that helps the cutting action;

it is often missing

or broken. There are two holes, one to each end of the

plane, that allow a

wooden sole (workman supplied) to be mounted onto the

plane.

In an early advertisement of the plane, Stanley

stated that the tool

"might very properly be termed a mechanical chisel." I term

it a

piece of mechanical crap. I hate this plane, but not nearly

as much as those

that are soon to follow.

#180 Rabbet plane, 8"L, 1 1/2"W, 2 1/2lbs, 1886-1918.

This is the first in a

series of cheap rabbet planes. They all resemble the #78, except

that there is no bullnose bed, nor is there a fence (these

are rabbet planes,

afterall). A large thumb screw activates the lever cap to

secure the cutter in

place, just like the #78's way of doing it.

This is the first in a

series of cheap rabbet planes. They all resemble the #78, except

that there is no bullnose bed, nor is there a fence (these

are rabbet planes,

afterall). A large thumb screw activates the lever cap to

secure the cutter in

place, just like the #78's way of doing it.

Both sides of the plane are ground flat, so it can be

used either left or

right handed. The right side of the plane has depressions

cast into it to

minimize the amount of area that had to be machined flat.

There is not much

else that distinguishes these boring planes. They are

useful, though I like

wooden ones much better. As is the case with the wooden

rabbet planes, a batten

must be laid on the wood's surface in order to regulate the

width of the cut.

The planes are japanned, with the later ones having

nickel plated trim (the

lever cap thumb screw and the depth stop thumb screw being

the nickel plated

parts). The planes have a bit of floral decoration cast into

the tote (kinda

reminds me of what you would see on a hearse or something

like that) just like

that used on the #78's. Toward the end of the

plane's production, the

tote was redesigned to have the fish scale pattern cast

into the tote, and

these models of the plane are found less often than those

with the floral

motif.

The depth stops are often missing from these planes.

You can snag a depth

stop from a #78, but seeing how many #78's are missing their stops as

well, you may have to

look awhile until you find one. If this plane is missing

the iron and/or lever

cap, you can pilfer one from a #78 since both are the same width

across the two

models. This plane never came with a depth adjuster, but

that matters not one

bit since the iron from any model of the #78 will fit this plane and its

spur-happy brother, the

#190.

However, if you want the plane to appear original, you

don't want to use an

iron from a #78 that has the milled slots in

the back.

Because they have no spur attached to the right side,

the planes didn't sell

nearly as well as the series that did - #190, #191, #192 - and Stanley finally

punted them from their

product line once some Einstein realized a spur is a nice

thing on a rabbet

plane (the wooden rabbet planes could also be bought

without a spur, so it must

have been a preference thing back then).

#181 Rabbet plane, 8"L, 1 1/4"W, 2 1/4lbs, 1886-1918.

Same as the #180, except it is narrower, and because of this you need to inspect the iron and lever cap as they may be ground down from the wider #180 to function as a replacement. If you see milled slots in the backside of the iron, it's not original to this or any other plane of the series.

#182 Rabbet plane, 8"L, 1"W, 2lbs, 1886-1918.

Same as the #181, except it is narrower. If this plane is missing its iron and/or lever cap, you're SOL until you can find one from a basket case example. This model uses captive lever caps that are held to the plane with a screw, like the #39 series uses. The lever cap can snap down at it bottom, where it places pressure on the lever cap, so check for that damage.

#190 Rabbet plane, 8"L, 1 1/2"W, 2 1/2lbs, 1886-1962.

Identical to the #180, except that this one has a spur, on its right side (ahead of the cutter), to score the grain. The astute observer will note that this plane far outlasted the #180, due to the simple feature of the spur. Apparently, this was lost on Stanley, where a spur is very nice to have on general purpose rabbet planes that are designed for rougher work, like these are.

This plane, and the two that follow, parallel the #180 series in casting

changes.

#190W Rabbet plane, 8"L, 1 1/2"W, 2 1/2lbs, 1941-1943. *

This plane is like the #78W, used to cut special rabbets for the installation of standard width weather stripping. It has a removable bottom guide that acts like a fixed fence.

#191 Rabbet plane, 8"L, 1 1/4"W, 2 1/4lbs, 1886-1962.

Same as the #181, except it has a spur.

#192 Rabbet plane, 8"L, 1"W, 2lbs, 1886-1962.

Same

as the #182, except it has a

spur.

Drumroll, please. We're about to view life from the tool gutter, so don your snorkel, and make sure your shots are current. It's time to go under.

But first, a precautionary note is in order. If you

should ever handle one

of these pieces of New Britain offal, be sure to do so with

the protection of

rubber suit and gloves. Handling them without such

preventive measures requires

immediate sterilization of any and all exposed flesh, lest

you be struck dead

in mere minutes by a particularly virulant strain of the

plane pox. You have

been warned!

#193 Fibre board cutting plane, 12 1/2"L, width? (who cares), 6lbs, 1933-1943.

Let's just say that this plane is an utter piece of junk, which Stanley made to cash-in on the tacky fibre board craze of the 1930's and leave it at that. Oh, this, and the next 3 are my most favorite planes to hate, in the whole wide world, right up there next to anything made by the Shelton Plane and Tool Co. Mere words fail to express just how much I loathe these planes.

#193A Fibre board cutting plane, blah, blah, blah...

Same as above except it has more junk with it to make that fibre board even more attractive. If you have one of these planes, and are wondering what parts came with it, or are even looking for the parts, you need more help than I can possibly give you.

Now it's time for a true story - no names were

changed to protect the

innocent. Or the guilty.....

One day, while out dumpster diving, looking for

bottles I could return to

claim the 5 cents deposit (10 cents in Michigan), I stumbled

upon one of these

guys. Startled, I whipped out my handy digicam, and took the

following

photograph of it in situ. Not wanting to touch it, for fear

of catching some

dreadful and incurable disease, I poked at what laid before

my eyes with a

stick to rearrange it. If you look closely, you can see all

the parts that came

with this tool (and I hesitate to call it that) which no one

will ever boast of

owning when the topic of collectible tools comes up at the

local bistro. Image

is below. Don't email me bomb threats if you turn to stone,

ok?

#193B Fibre board cutting plane, yeah, we know...

ZOINKS! Even more stuff to make your fibre board the best on the block! The previous three planes are the ne plus ultra of Rube Goldberg plane design, winners of the prestigeous That's Incredible/Why'd They Do That Award for 60 consecutive years. Do America a favor and destroy every one of the above three models you may encounter, so that its competition might have a fighting chance in this year's awards. Please?

#194 Fibre board beveler plane, 8 3/8"L, the width of a razor blade, 1 1/2lbs, 1936 - 1958.

Oh joy, another plane for fibre board, but this one is special (can you say special?). It cuts a chamfer up to 3/8"W on fibre board. One woulda thought world peace was at hand with the introduction of this marvelous piece of technology, where folks worldwide would busy themselves with bevelling fibre board all day. But, no, we had two wars to suffer through during its production. Hmmm, is there a cause and effect here, somewhere?

#195 Hard board beveler plane, 8 1/2"L, the width of a razor blade, 1 1/2lbs, 1937-1943. *

The

setting - The

Stanley Board Room, President speaks, "Hey, fellas, let's

make a plane

that bevels hard board." Underlings respond, "Swell idea

chief! It

will sell like hotcakes!" Wrong, guys. You can't make shit

shine. The only

redeeming thing about this plane is that it's rare and

collectible. I would

never stoop so low to own one. They and the #194 are butt ugly!

OK, we're back. Hope you didn't suffer terribly while

viewing Stanley's

sphacelous underbelly.

#196 Curve rabbet plane, 9"L, 1"W, 3lbs, 1912-1934. *

Here's a funky plane that

makes you wonder how it works, and why it was ever invented.

But invent it J.W.

Montague did. Stanley even embossed their name and the model

number along the

right side of the main casting, so they must have thought it

a good idea.

Here's a funky plane that

makes you wonder how it works, and why it was ever invented.

But invent it J.W.

Montague did. Stanley even embossed their name and the model

number along the

right side of the main casting, so they must have thought it

a good idea.

This plane is designed to cut a curved rabbet (both

on an outer edge and an

inner edge, like on a picture frame) - something that every

woodworker is

chomping at the bit to do, day in and day out. That's why

this plane was

offered for sooooooooooo long. Sorry, Stanley, it was a dud

as curved rabbets

ain't that common, and by the time the thing made its debut,

there were

machines that could do the job. "Too stupid and too late" is

this tool's

epitaph.

It's kind of an ugly looking plane that sort of

resembles a modified #39 (the dado

planes), and uses the same sort of lever cap to hold the

iron in place as the

dado plane series uses; i.e., a lever cap that is held to

the main casting with

a screw. Check that the lever cap shows no damage or

repairs as it's possible

to snap this style of lever cap. Also make sure that the

rightmost edge of the

lever cap is flush with the machined surface on the right

of the plane.

It has a #78-like tote, which is textured in the typical style

of the planes

produced during this era - a fish scale like surface.

Directly in front of the

tote is a #45-like cutter adjustment wheel,

with a pin that

engages a cutout in the cutter. The cutter adjusting

mechanism is held captive

to the main casting by means of two loop-like projections

arising just in front

of the tote. Check for any signs of cracks or repairs on

the projections.

The cutter is set at a skew, and is is actually two

cutters, one on top of

the other. The lower cutter, which cuts across the width of

the rabbet, is

similar to the cutter of the #78 in that it widens to the right

just above the

cutting edge. The upper cutter is rather angular at the

business end, and its

rightmost edge acts as a spur to score the grain to leave

the side of the

rabbet cleanly cut. The rest of the upper cutter has a

bevel across the bulk of

its width so that it acts like a cap iron. These two

cutters are secured

together with a screw that's positioned below the lower

cutter. The heel (top)

of the lower cutter has the notch cutout.

The plane has a very short 'sole', roughly 1" long so

that the plane

can accomplish its function over differing radii. Directly

behind the sole, the

main casting arches upward and then straightens out along

the rest of the

casting. The main casting is fashioned this way so that

there is no hindrance

as the plane follows the contour of the piece, especially

when cutting rabbets

on an inner edge.

The depth and width of

the rabbet are regulated by two adjustable mechanisms

forward of the cutter.

One acts as a fence to follow the contour of the work, and

the other acts as a

depth stop. The fence measures roughly 1/2" long and has a

slight curve to

it. The depth stop, very much like those used on the #45, has a

slight curvature at its leading edge. Each of these is

adjusted by turning a

captive screw (one for each), and is then secured in

position by a thumb screw.

Check the casting about the area of the captive screws for

any breakage or

cracks.

The depth and width of

the rabbet are regulated by two adjustable mechanisms

forward of the cutter.

One acts as a fence to follow the contour of the work, and

the other acts as a

depth stop. The fence measures roughly 1/2" long and has a

slight curve to

it. The depth stop, very much like those used on the #45, has a

slight curvature at its leading edge. Each of these is

adjusted by turning a

captive screw (one for each), and is then secured in

position by a thumb screw.

Check the casting about the area of the captive screws for

any breakage or

cracks.

Both the fence and depth stop are carried on a

removable nose piece, which

is secured to the plane's body with a slotted screw. The

nose piece is removed

when doing confined or bullnose work. The joint between the

nose piece and the

main casting is a broad tongue and groove, similar to the

way the Bed Rock frog

mates with its receiver. I've seen a few planes that have a

hairline crack in

the nose piece's casting, where it mates with the main body,

so check that area

thoroughly.

These planes are too valuable to use, but if you have

more money than

brains, and want to use this contraption, you'll find it a

funky beast unless

the cutter and spur are both very sharp and that they are

set finely. When you

get frustrated at the thing, you can always pack it in your

backpack when

mountain climbing as all that nickel plating makes it a

better reflector than

it is a tool.

[ START ] |

[ PREV ] | [ NEXT

] | [ END ]

[ HOME

]

Copyright

(c) 1998-2012 by Patrick A. Leach. All Rights Reserved.

No part may be

reproduced by any means without the express written

permission of the author.